6 Practices for a Safe Workplace in the Aerospace Industry

In the dynamic world of aerospace, safety isn’t just a priority—it’s a fundamental necessity. From bustling hangars to the intricacies of aerospace industry regulations, ensuring safety comes as a complicated task. In this article, we delve into the best practices for ensuring a safe workplace in your facility, focusing on essential aspects such as Personal Protective Equipment (PPE), safety protocols and fostering a culture of safety. We’ll simplify key strategies that are not only implemented to protect employees but also uphold the highest safety standards and well-being in the dynamic and challenging aerospace industry.

1. Wear High-Quality PPE

The intricate and complex nature of tasks, such as electrical work and heavy welding, coupled with the presence of potentially hazardous materials and machinery, necessitates the use of reliable PPE to safeguard workers. From protective clothing and gloves to safety goggles and ear protection, each piece of equipment plays a crucial role in minimizing the risk of injuries and ensuring a safe working environment. High-quality PPE not only shields workers from physical harm but also instills confidence and peace of mind, allowing your workers to focus on their tasks with utmost precision and efficiency.

2. Use Proper Tools

Using proper tools is important due to the industry’s rigorous demands for precision and safety. The complexity of aircraft components and systems necessitates specialized tools designed to meet stringent standards and tolerances. Each piece plays a critical role in ensuring the quality and reliability of aerospace products. Using improper or substandard tools can lead to errors and safety hazards, compromising the integrity of the final product and putting your workers at risk.

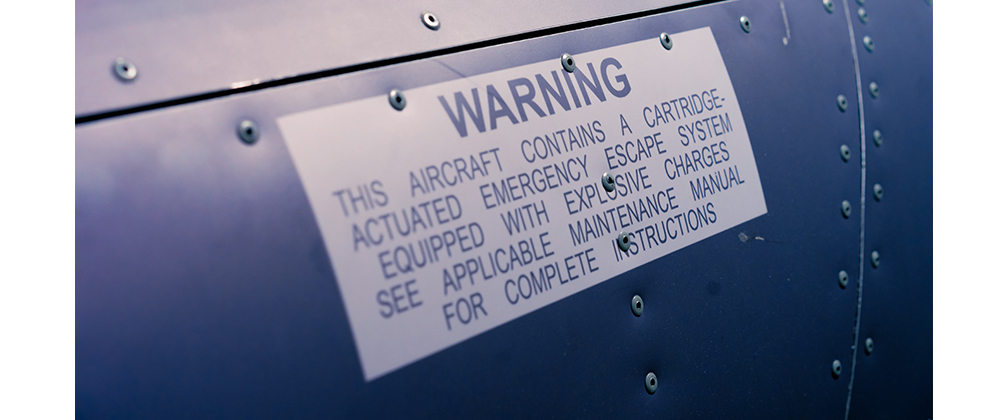

3. Understand Safety Signs

Signs are commonly placed to communicate essential information about potential hazards, safety procedures, emergency exits and protective equipment requirements. Workers need to be familiar with the meaning of various safety signs, such as warning signs for high-voltage areas, danger signs for hazardous materials and emergency exit signs for evacuation routes. Misinterpreting or ignoring safety signs can lead to serious consequences, including injuries, equipment damage and disruptions to operations.

4. Communicate Effectively

In an industry where precision and attention to detail are of the utmost importance, clear communication between team members, engineers and supervisors is essential for coordinating tasks and conveying technical information promptly. Miscommunication or lack of communication can lead to errors, delays and safety hazards, jeopardizing the quality of aerospace components and the well-being of your personnel.

5. Reduce Physical and Mental Stress

Aerospace workers often face high-pressure situations, tight deadlines and complex tasks that can lead to physical strain and mental fatigue if not managed effectively. Implementing measures to minimize physical stress, such as ergonomic workstations, proper lifting techniques and regular breaks, helps prevent injuries and promotes employee well-being. Additionally, addressing mental stress through stress management programs, counseling services and workload adjustments can enhance job satisfaction, productivity and improve company culture.

6. Secure a Safe Workplace with Solutions from Our Partner Suppliers

One of the most effective strategies for securing a safe work environment is making sure your team has access to high-quality tools, equipment and solutions. Check out some of the top products for aerospace applications from our partner suppliers:

The 8511 N95 Disposable Respirator from 3M™ is designed to protect workers from airborne particles such as dust and pollen. The molded cup design provides a comfortable and secure fit, making it ideal for extended wear.

3M also offers the E-A-R Push-Ins SofTouch Ear Plugs engineered to adjust to the shape of a worker’s ear canal, helping to create a comfortable noise-reducing seal.

SemperForce black nitrile examination gloves from Sempermed® are crafted for rigorous work settings that prioritize safety and comfort. Their textured surface ensures a firm grip, making them ideal for demanding tasks.

The CFC Free Electro Contact Cleaner from ITW ProBrands is a fast-evaporating contact cleaner formulated to remove oil, grease, dirt, flux and other contaminants. This cleaner leaves behind no residue and low odor, making for a safe and comfortable working environment.

Meltblown Technologies offers Absorbent Pads designed with soft, super-absorbent fiber thermally bonded with a thin layer to each side of a coarse-fiber, meltblown polypropylene. These composites absorb quickly, reducing slips, trips and falls.

View more products from our partner suppliers.