Solve 5 Medical Device Assembly Challenges with Henkel’s New Light Cure Adhesives

Medical device manufacturing demands more than just precision—it requires processes that are fast, repeatable and fully compliant with industry standards. Whether you’re assembling disposable devices for single-use procedures or producing rigid instruments for repeated use, you need adhesives that can keep up with the complexity of modern medical assembly lines.

Henkel’s latest light cure adhesives—LOCTITE® AA 3961 and LOCTITE® AA 3963—are designed to address the most common pain points in production, delivering speed, versatility and reliability.

1. Bonding Dissimilar Materials

Modern medical devices rarely use just one material. A single product might combine stainless steel, polycarbonate, ABS, acrylic or other specialty plastics. These materials vary in surface energy, making them difficult to bond with a single adhesive. Traditional options may require primers or multiple adhesive types, which slows production and increases complexity.

Both LOCTITE® AA 3961 and AA 3963 offer exceptional adhesion to a wide variety of metals and plastics without primers. They deliver high bond strength on stainless steel, polycarbonate, ABS and acrylic—allowing manufacturers to streamline their adhesive inventory and reduce setup changes. This versatility means one adhesive can handle multiple stages of the assembly, improving efficiency and consistency across different product lines.

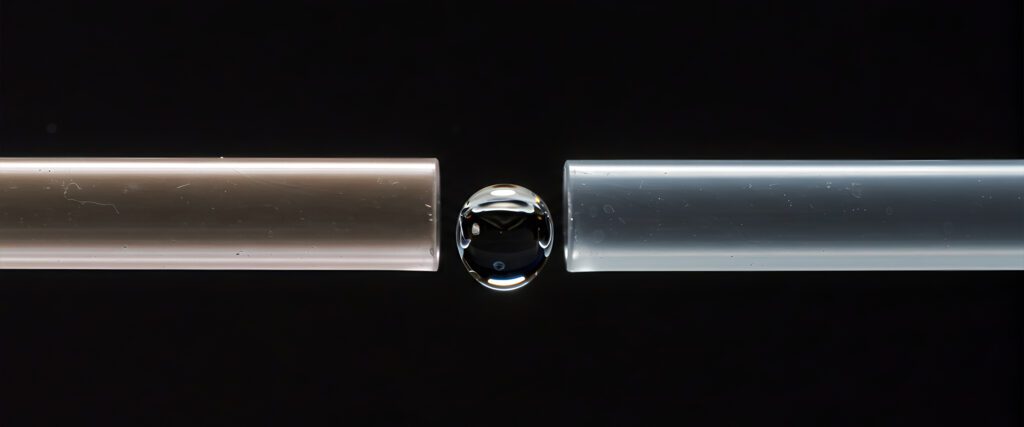

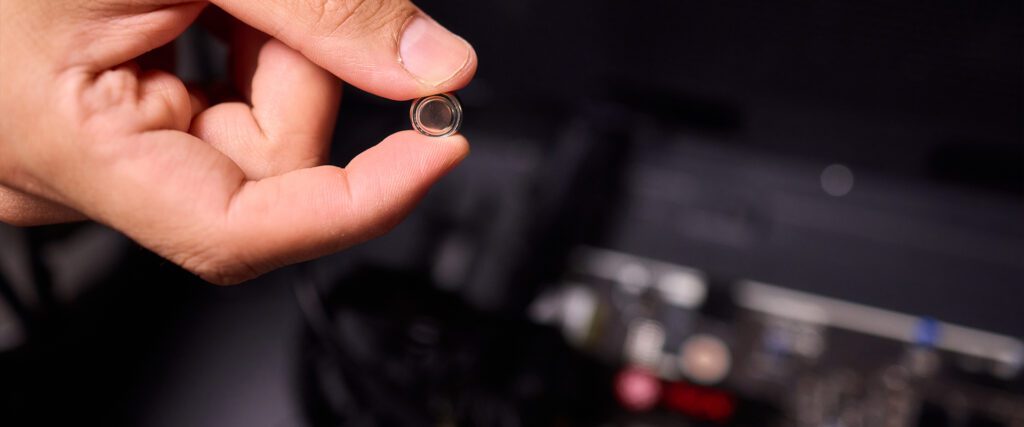

2. Maintaining Precision in Small or Complex Assemblies

Devices are getting smaller, and components are often assembled in extremely tight spaces. Adhesives need to wick into narrow gaps without flooding the surrounding area or adding unnecessary weight. Over-application can lead to excess squeeze-out, contamination of moving parts, or aesthetic defects.

LOCTITE® AA 3961 is an ultra-low viscosity, wicking-grade adhesive designed for precision bonding in confined spaces. It flows into micro-gaps, ensuring complete coverage without over-application.

LOCTITE® AA 3963 also offers a low-viscosity profile for accurate placement while maintaining strong, rigid bonds. This precision reduces waste, eliminates rework, and supports consistent results on complex, high-value devices.

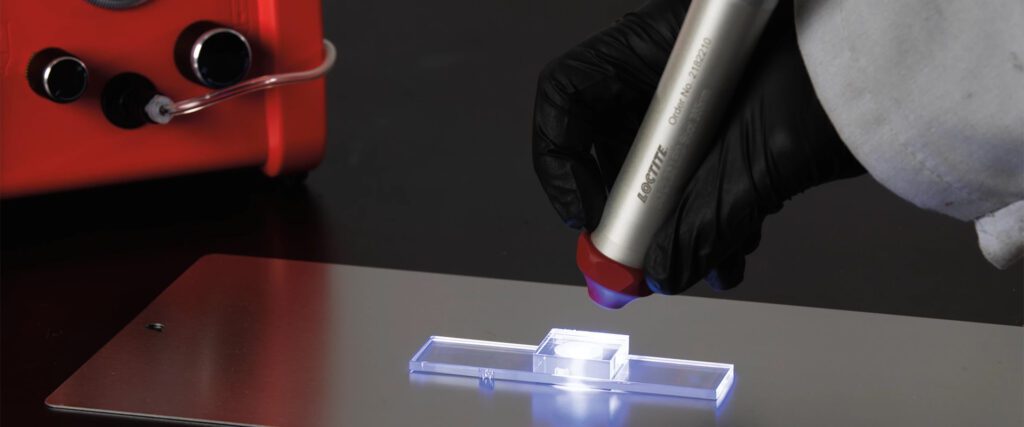

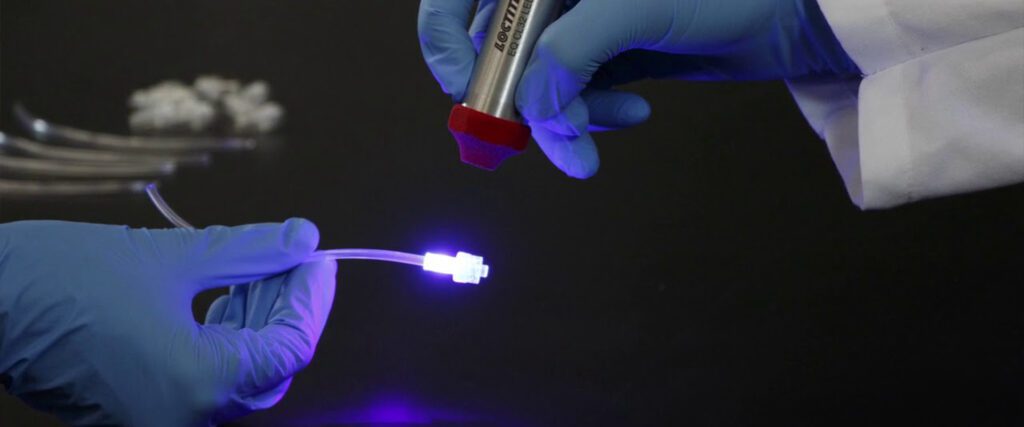

3. Reducing Cure Time Without Sacrificing Quality

Long cure times create production bottlenecks, slowing throughput and increasing labor costs. In fast-paced assembly environments, even a few extra seconds per bond can add up over thousands of units.

Both Henkel light cure adhesives cure rapidly under the right wavelength of light, delivering tack-free bonds in seconds. This speed allows manufacturers to move directly from bonding to inspection or packaging without lengthy delays. The quick set time also minimizes the need for temporary fixtures or clamps, freeing up space and resources on the production floor.

4. Ensuring Durability in Sterilization and Use

Many medical devices must endure sterilization—whether through autoclaving, ethylene oxide, or gamma radiation—without losing bond integrity. Adhesives that crack, degrade, or yellow under these conditions can compromise device safety and regulatory approval.

Henkel’s adhesives form rigid, high-strength bonds that maintain performance through common sterilization methods. Their clarity allows for visual inspection, helping quality teams verify complete adhesive coverage. This durability ensures devices remain safe and functional over their intended lifespan, even in harsh environments.

5. Meeting Regulatory Standards for Medical Applications

Adhesives used in medical devices must pass strict biocompatibility testing to ensure they are safe for patient contact. Achieving ISO 10993 compliance can be time-consuming and costly, and failing to meet these requirements can delay product launches.

Both AA 3961 and AA 3963 are ISO 10993 tested, helping manufacturers fast-track their validation processes. By choosing adhesives with proven biocompatibility, you reduce regulatory hurdles and lower the risk of delays. This compliance, paired with their bonding performance, makes these products an ideal fit for both disposable and reusable medical devices.